Tests

Test Lab for Evaluation and Qualification of Optoelectronic Components and Sub-Systems

-

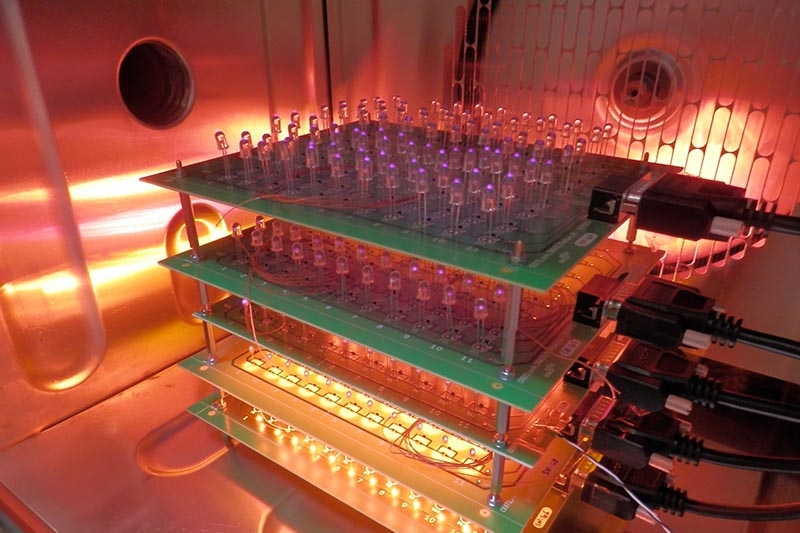

Endurance / Reliability tests

- Temperature regulation from 25°C to 150°C

- Current/voltage control

- Current/Voltage/Optical Power Tracking

- Controlled atmosphere: aging in air, nitrogen... -

Climatic Tests

- Temperature storage from -70°C to 300°C

- Storage under controlled humidity up to 95% RH

- Temperature cycling up to 15°C/min (thermal cycling and thermal shock)

- Controlled atmosphere: aging in air, nitrogen...

- Aging under polarization

- Tests in dry air: dew point - 50°C -

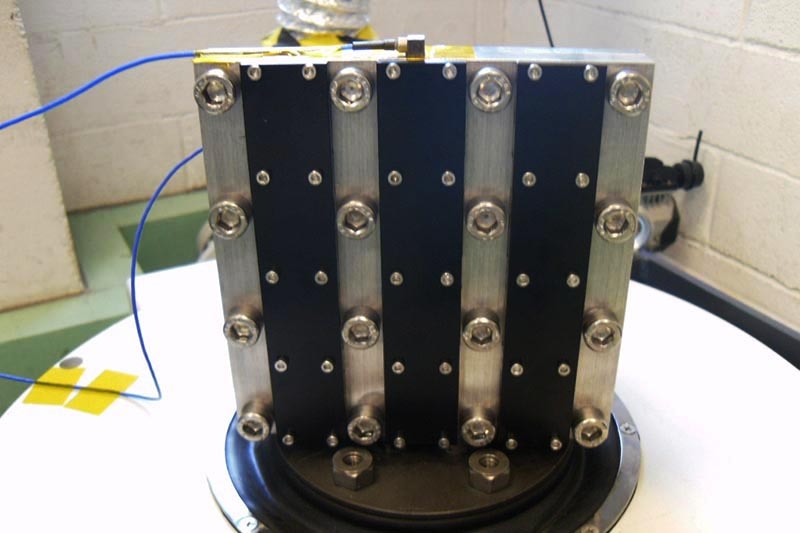

Vacuum tests

- Primary and secondary vacuum chamber: down to 10-7 mbar

- In-situ monitoring: optical, electrical, thermal, pressure and residual gas...

- Vacuum thermal cycling -

Mechanical tests : shock vibration

- Fibre pull with force monitoring

- Vibration, shock, shaking with monitoring of electrical / optical discontinuities -

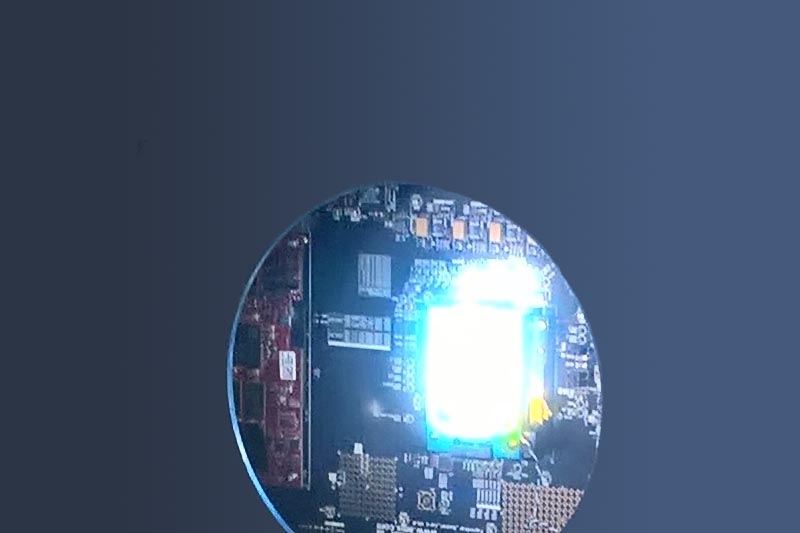

High directivity and high power solar simulator tests

- Testing of materials and components under solar radiation

- Strong power, strong directivity

- If necessary, combination of vacuum and temperature tests -

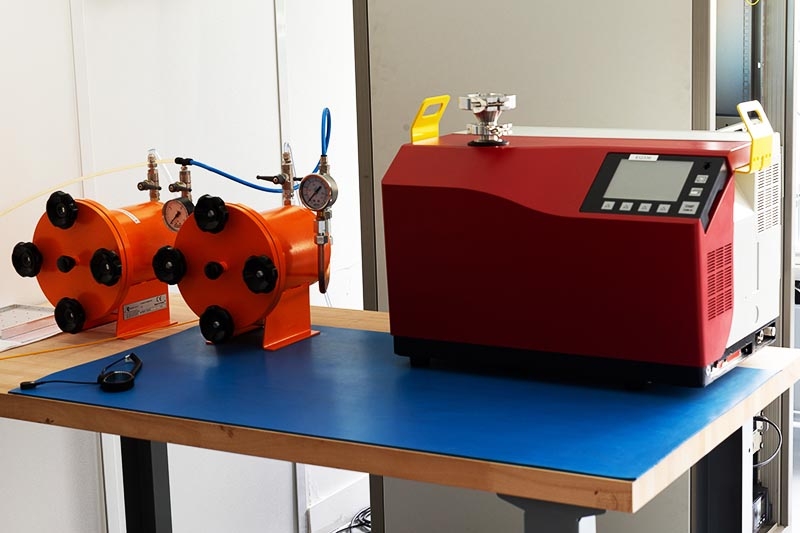

Hermeticity test, leak tests

- Detection of fine leaks and gross leaks

- Measurement of the hermeticity rate (Helium detection) -

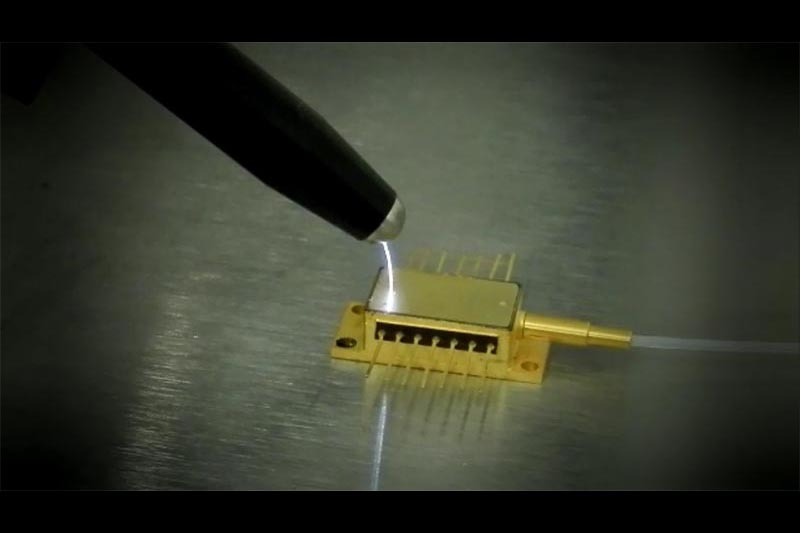

ESD tests : electrical discharges

- Resistance to electrostatic discharge, ESD

- Electrical Over Stress, EOS

- High optical power testing to failure

(COD -Catastrophic Optical Damage)

AdvEOTec carries out different types of tests campaigns, regular or specific, according to its clients’ needs.

REGULAR TESTS | ACCORDING TO THE STANDARDS | |

CLIMATIC TESTS | RTC TESTS : Rapid temperature change TCH TESTS : Thermal cycling in humidity STC TESTS : Slow temperature change HTS TESTS : High-temperature storage LTS TESTS : Low-temperature storage TS TESTS : Thermal shocks | - GR 468 - GR 1209 - GR 1221 - MIL-STD-750 - MIL-STD-883 - … |

MECHANICAL TESTS | VIBRATION AND SHOCK TESTS : -------------------------------------------------- FIBER PULL TESTS : Pull test | - IEC 6006 - IEC 68-2-34 à 68-2-37 - MIL-STD-750 - MIL-STD-810 - MIL-STD-883 - NF EN 2591-6402 - NF EN 2591-6403 - NF EN 60068-2-6 - NF EN 60068-2-64 - … --------------------------------------------------- - GR 468 - GR 1209 - … |

VACUUM TESTS | TVAC TESTS : | - Customer-specified standards - ESCC - … |

AdvEOTec draws up with its clients’ specific tests campaigns according to the applications or the use’s environment. Among these tests, there are for example :

– Leak tests

– Sunlight conditions tests (solar simulator)

– Accelerated ageing tests under controlled environment

– Electrostatic discharges tests

– Mechanical tests with optical and electrical microcuts monitoring

– …

These campaigns are divided in several steps and are carried out according to certain standards :

– Step 1: Components choice (supplied by the client or searched and provided by AdvEOTec);

– Step 2: Conception of the tests, preparation and metrology carried out by AdvEOTec;

– Step 3: Management and implementation of the tests, characterizations, interpretation and analysis;

– Step 4: Final report (English or French) on the entire prestation.

Specific tests :

Leak tests | - MIL-STD-883 Method 1014 - MIL-STD-750 Method 1071 - ISO 20484 :2017 - ECSS-S-10-03A Method I et Method II |

Sunlight conditions tests | - DIN 75220 - ISO 9022-9 - IEC 60068-2-5 - MIL STD 810G Method 505.5 - ISO 9845-1 - IEC 60904-9 - ASTM E490 - ASTM E927-10 - ASTM G173-03 |

Electrostatic discharges tests | - EN 61000-4-2 - GR 468 - IEC 61000-4-2 - IEC 61326 - ISO 10605 - MIL-STD-750 Method 2020.3 - MIL-STD-883 Method 3015 - … |